Equipment Details

We believe in functional design.

Our goal at Beltech, is to provide equipment that is the highest level of functional design. Our units are strong, efficient and simple.

Please contact us for more information at (905) 332-6003 or e-mail to info@beltechengineering.com.

Travel Exhaust Systems

Close Capture Exhaust for Mobile Sources

The Beltech Travel Exhaust System minimizes the exhaust volume required by maintaining a close hood with the mobile source. Our exhaust hood will follow the path of your source.

This system is traditionally for the foundry industry and follows the ladle from the furnace to the mold, but can be adapted for any application where exhausts need to be controlled while moving container.

The system is installed along the crane runway or monorail track. As the crane travels along its runway/monorail, it pulls the exhaust transfer hood along. Our Travel Exhaust duct has a seal that opens as the hood tracks along the duct, providing consistent suction along the cranes full path.

Beltech has designed and installed Travel Exhaust systems with straight and curved runs in applications dealing with high heat, sparks, noxious gases, designated particulate, nuisance dusts and vapours. If absolute capture is critical to your process, the Travel Exhaust System provides the capture you require with the minimum amount of exhaust volume, providing you with the best performance at the lowest operating costs.

Please contact us for more information at (905) 332-6003 or e-mail to info@beltechengineering.com.

TravelairTM - Crane Cab HVAC

A True Lifesaver System

Beltech TravelairTM system is a unique method to bring fresh air from outside to the crane cab without the need for bridge-mounted units. All our filtration and A/C units are installed outdoors. A single duct is installed along the length of the crane runway and several cranes can simultaneously draw clean, fresh, cool air to their cabs and electrical rooms.

The System

Fresh air is drawn into our outdoor HVAC units and into the pressurized, insulated duct running along the crane. The TravelairTM car runs along the duct, opening a seal and extracting the cool, fresh air, allowing it to flow into the crane cab and electrical rooms.

Always Stay Positive!

Our system always maintains a positive pressure since a continuous flow of fresh air is supplied to the cab and electrical rooms. Bridge mounted units can only supply positive pressure while the filters are clean, once the filters are clogged, the bridge-mounted unit cannot pressurize the cab due to the reduced flow.

No Recirculation

Beltech TravelairTM system is always suppling fresh air, so no recirculation of potentially contaminated air. Bridge-mounted units recirculate 80-90% of the air, which means that the contaminated air that came into the cab when the door opened is no being recirculated and breathed by the operator.

Low Maintenance

The Beltech TravelairTM system meets the highest air quality requirements for crane cabs under the most adverse industrial conditions of heat, particulate, and gases, while requiring the least amount of maintenance. Filters, fans, and air conditioning units are installed outside, away from theses harsh conditions.

Crane electrical rooms are also kept dust-free and cool, through positive pressure and a continuous supply of conditioned air. The large heat load of todays crane electrical rooms is controlled reducing costly downtime.

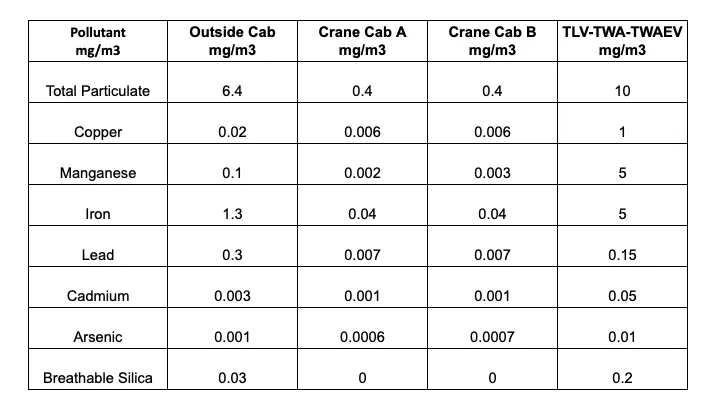

The Beltech TravelairTM system is highly effective in removing and controlling the concentrations of the industrial pollutants commonly found in industrial environments. Below are results of an investigation carried out in a typical steel mill equipped with the Beltech TravelairTM system, and its effect on the crane operator’s environment as compared to ambient conditions. This runways has two cranes on the same system; Crane A and Crane B.

Air Quality Test Results

BulkliftTM

No Moving Parts Pneumatic Elevator

The System

The Beltech BulkliftTM System is a space efficient, low maintenance air operated material elevator with absolutely no moving parts; no valves, no actuators or seals. The Beltech BulkliftTM harnesses the hydrostatic pressure of a fluidized material to transport the product in both vertical and combined vertical and horizontal arrangements. Sealed feeds are not required and thus conveyor belts, vibratory conveyors and ambient chutes can be used as opposed to traditional pneumatic conveying systems that required a sealed pipe or chute feed. The advantage of no moving parts makes the BulkliftTM ideal for pneumatic conveying of highly abrasive or high temperature products to beyond 900°F.

Why install a Bucket Elevator when you can install a Pipe?

Installation of the BulkliftTM is as easy as installing any pipe run. Locate the BulkliftTM vessel and the Separator/Receiver and the rest is just flanged pipe. A line carrying hundreds of tons per hour can be passed through floors and between equipment with the easy of a water line.

No Valves, No Actuators?... No Problems

The majority of the problems associated with conventional pneumatic conveying systems have to do with leaking valves or faulty actuators. The Beltech BulkliftTM avoids these problems by eliminating these items. By doing this, maintenance costs are substantially reduced and time between required maintenance is significantly extended. Since the system works at atmospheric pressure there is no need for air locks or actuators. The BulkliftTM is truly a "No Moving Parts" low maintenance system.